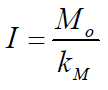

be calculated as follows:

Current through motor = torque produced divided by the torque constant

Further Considerations:

· The constant current operation of a DC motor produces constant output torque regardless of speed.

· Given a constant load (i.e. torque) the speed of a motor is solely dependent on the voltage applied to the

motor.

· Power is the product of speed and torque. The maximum power of a DC motor is produced at the

operating point that is defined by operation at half the no-load speed and half the stall torque. Seldom will

a motor be operated at maximum output due to thermal considerations.

· The general rule of thumb for operation of a DC micromotor is to operate the motor at approximately 90%

of its no-load speed and from 10% to 30% of its stall torque. This is also the motor’s most efficient area of

operation.

· For use with gearing, the motor should be selected for the minimum speed practical by choosing a motor

with higher voltage ratings than the available voltage supply. This will result in lower noise generation and

better life characteristics.

· For DC motors operated at a constant voltage, the speed and torque produced are inversely related. The

higher the torque produced, the lower the speed of the motor will be.

· Other factors, of course, enter into the selection of an appropriate motor. Such factors may include size,

environmental conditions, weight, required life, etc. As an example, assume the following application

parameters:

Initial Motor Choice Parameters:

· Available voltage (V) = 20 Volts DC

· Output torque required (M) = .425 oz-in

· Output speed required (n) = 5,000 rpm

· Minimum physical size is desirable

· Ambient Temperature= 22°C

Given these parameters, it is unlikely that a standard catalog motor will fulfill all parameters simultaneously

since they are not independent. The selection process consists of finding the best fit.

Contact: Sammy

Skype:

Tel:

Email: sammyfu@electricmotorscn.com

Add: 5th Floor, Building 3, Huafeng Zhenbao Industrial Park ,Beihuan Road, Shiyan Street, Bao'an District, Shenzhen City, China.