1 Introduction

Brushed DC motors have great torque coefficient, strong overload capacity, high reliability advantages, are widely used in motion tracking control of wheeled mobile robots and spacecraft ground mobile base[1]. Wheeled mobile robot drive motor control system is the executive body of the mobile robot, the motor control system plays a vital role for the smooth and rapid operational of the robot system. The speed tracking performance of driving motor will directly affect the mobile robot motion tracking effect. Thus, drive motor need to track the desired angular speed quickly and accurately in high-precision tracking control of wheeled mobile robot.

However, when a brushed DC motor running at low angular speed, system will appear movement which is not smooth

phenomenon, due to the friction torque. Steady state error, occurrence of instability and limit cycle oscillation may be

2 Brushed DC motor model

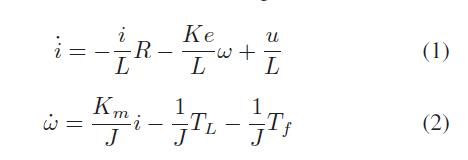

In this paper, the simplified mathematical model of the brushed DC motor is shown as following:

where Tf describe friction model. Among the friction model, Stribeck model can describe the relationship between

speed and friction torque more accurately. Thus, in order to obtain better control performance in the process of design

controller, Stribeck model is a better choice. Stribeck model

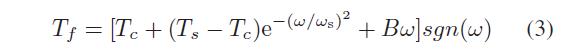

is as follows:

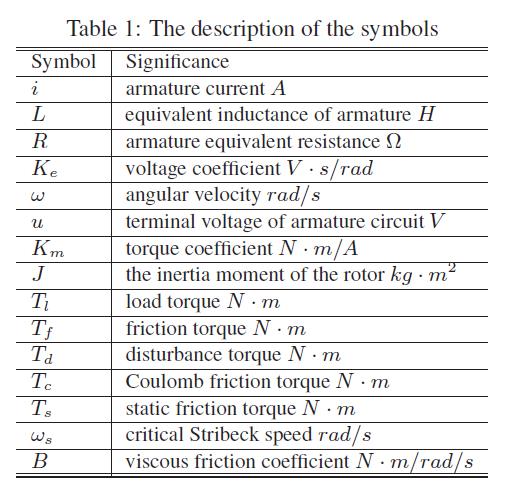

Wherein, the parameters Tc, Ts, ωs, B can be determined experimentally. The description of the symbols in the formula

are shown in Table 1.

In value, the voltage coefficient Ke is much smaller than the torque coefficient Km, therefore it can be considered the

current loop and the speed loop decoupling. Using cascade control for DC motor angular speed control is feasible. In

this paper, the controller of speed loop and current loop design respectively. In the industry,the brushed DC motor control strategy based on current loop and speed loop are often used.

Contact: Sammy

Skype:

Tel:

Email: sammyfu@electricmotorscn.com

Add: 5th Floor, Building 3, Huafeng Zhenbao Industrial Park ,Beihuan Road, Shiyan Street, Bao'an District, Shenzhen City, China.