Brushed DC Motor Basics III

Brushed

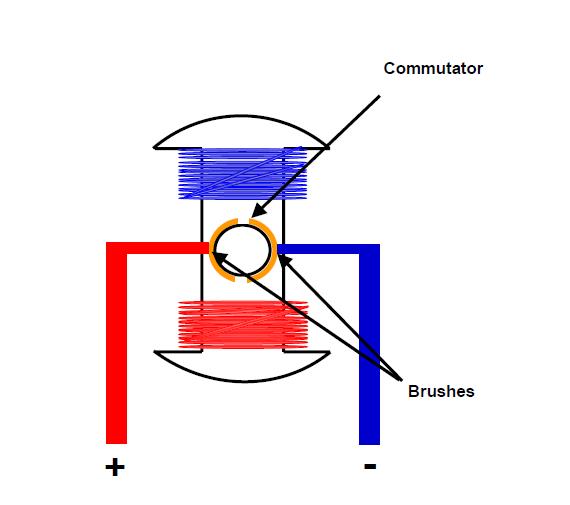

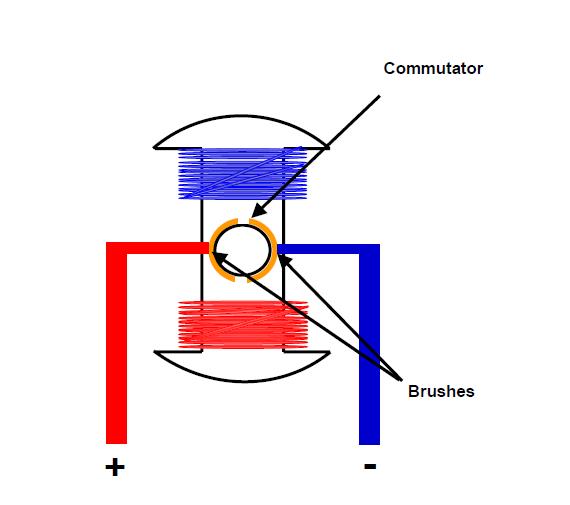

DC motors do not require a controller to switch current in the motor windings. Instead, it uses a mechanical commutation of the windings. A copper sleeve ( commutator ), resides on the axle of the rotor. As the motor turns, carbon brushes slide over the commutator, coming in contact with different segments of the commutator. The segments are attached to different rotor windings, therefore, a dynamic magnetic field is generated inside the motor when a voltage is applied across the brushes of the motor. The brushes and commutator are the parts of a

brushed DC motor that are most prone to wear.

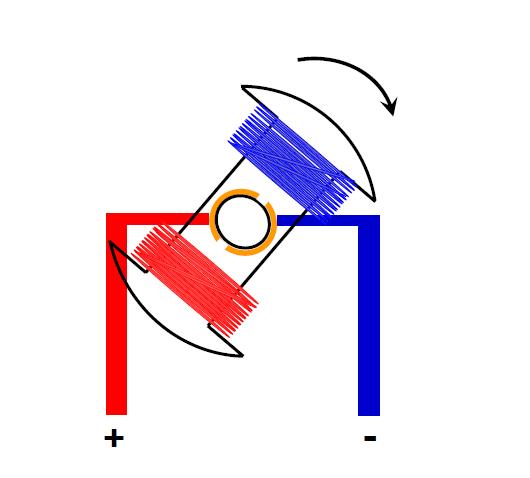

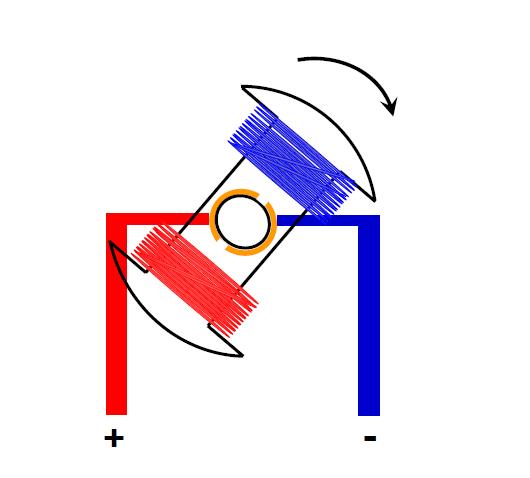

So, as the rotor rotates inside the stator, the brushes rub the different segments of the commutator supplying a charge to that segment and its corresponding winding.

As the bushes pass over the commutator gaps the supplied electrical charge will

switch commutator segments.

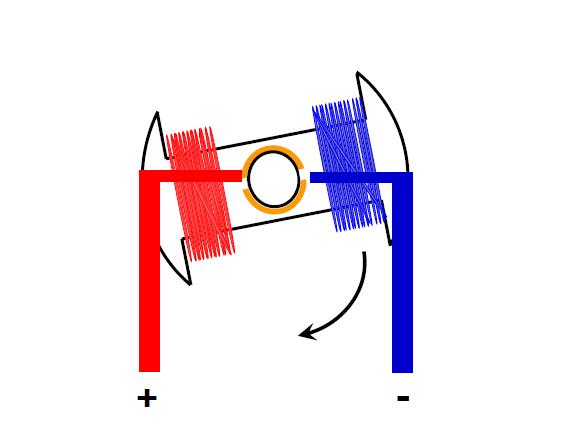

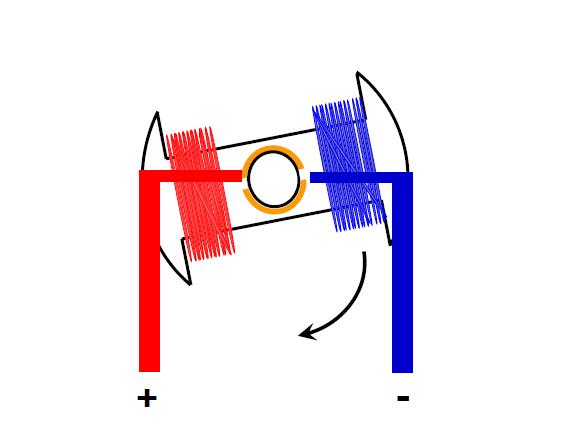

Thus, switching the electrical polarity of the rotor windings. This will create an

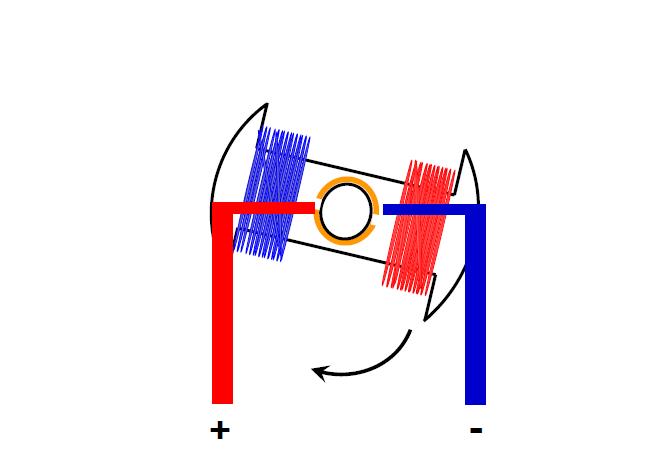

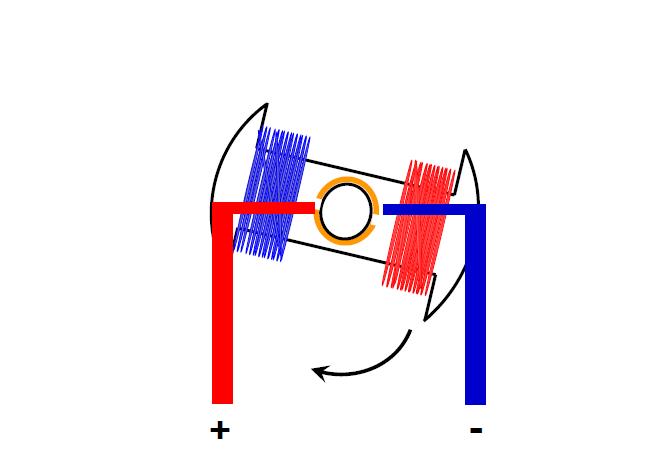

attraction of the different polarities and keep the rotor rotating within the stator field.

This process will continue as long as a supply voltage is applied.