Hybrid powertrain has the advantage of higher fuel economy performance and lower emission through hybridization with other energy storage devices such as battery or super capacitor. Electric Motor is a key part in hybrid powertrain. Motor characteristic must be carefully investigated before it is integrated into the Powertrain to ensure the motor efficiency, torque respond speed and other performances are qualified for use .

Most motor for hybrid is controlled via CAN bus. Key information such as current, voltage, motor speed, motor torque and temperature is broadcasted on CAN bus. CAN bus is adopted for measurement interface. Additional sensors is not used, making the test system clear and easy to build.

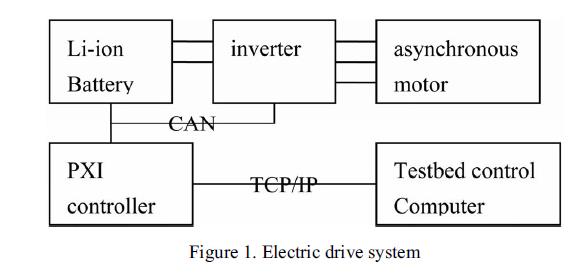

This paper presented a test system based on filed bus, including CAN bus, RS-232, and TCP/IP. LabVIEW is used as the system integration tool. Three computer High performance is achieved using LabVIEW develop software environment and NI hardware at a much lower cost than specialized RCP tools such as dspace. Based on this platform, motor parameters were abstracted.

II. ELECTRIC DRIVE SYSTEM

The hybrid powertrain system includes asynchronous motor, DC-AC inverter, a controller and a li-ion battery. The structure is demonstrated as Figure 1. A PXI controller running NI realtime OS is used as Rapid prototype controller. PXI controller get realtime physical value such as motor speed, motor current and battery voltage from can bus, and then send the data to testbed control computer, where the dynamic data is recorded to txt file. DC-AC inverter get torque command from PXI, then it control the motor by direct torque control(DTC) technology. The motor can work inboth drive mode and generator mode.

Contact: Sammy

Skype:

Tel:

Email: sammyfu@electricmotorscn.com

Add: 5th Floor, Building 3, Huafeng Zhenbao Industrial Park ,Beihuan Road, Shiyan Street, Bao'an District, Shenzhen City, China.